Effective Tips for Buying Bag Fabrics in Bulk? Here Are Some Cost Saving Tips

For manufacturers, distributors and businesses involved in the production line, buying bulk fabric is essential. Bulk purchase often leads to significant savings but it carries with itself a certain amount of risk. Bad quality fabric and inconsistent product supply are some of the risks connected with bulk buying.

This blog will talk about how to reduce costs and maintain the product quality at the same time.

Understand Your Requirements Before Ordering

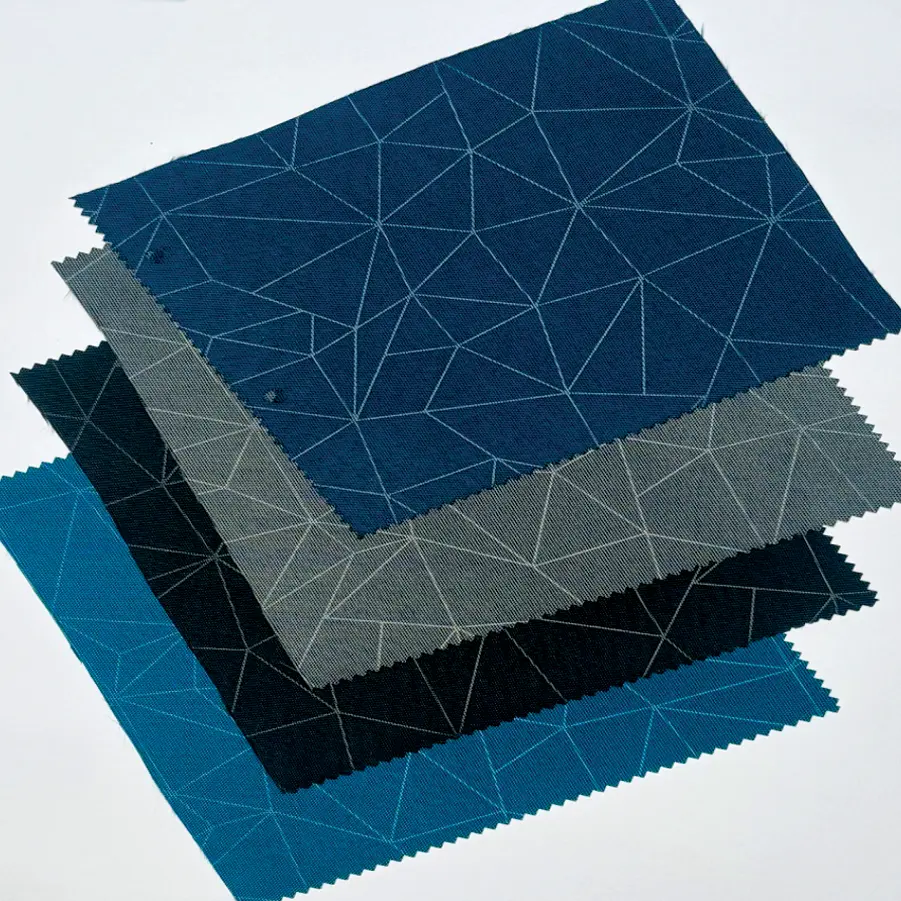

Before you go ahead and order the product, it is necessary to understand your requirements. There are various Bag Fabric types and materials available. Choose the ones appropriate for your business.

- Fabric type (cotton, polyester, PU/PVC coated, canvas, etc.)

- Coating requirements

- Quantity required and usage frequency

Keeping all these pointers in mind, buyers can avoid buying extra or buying less fabric than is required. You can reduce additional expenditure by planning everything ahead.

Consider Manufacturer vs. Distributor

Let us go through this quick table. It compares the difference between when your source from the manufacturer and when you source from the supplier.

|

Option

|

Pros

|

Cons

|

|

Manufacturer

|

Lower per-unit cost, custom specifications, consistent batch quality

|

Higher minimum order quantity, potential need for long-term commitment

|

|

Distributor

|

Smaller minimum orders, faster delivery, variety of options

|

Higher per-unit cost, limited customization, possible batch inconsistency

|

Most of the bulk fabric buyers go for direct manufacturer relationships, specially when ordering a large number of products. Also, direct sourcing paves way for future buying as it provides better value in the long run.

Bargain Smartly

When making a deal, consider the following factors:

- Bulk Discounts: You can save a great amount of money when buying in bulk. Your procurement partner offers decent discounts based on the volume of fabric ordered.

- Flexible Payment Terms: Talk to the partner about flexible payment options and credit options. (if any)

- Long-Term Agreements: When you associate yourself with a manufacturer for a long time, you get greater discounts in the future. These are the benefits of long term association.

Evaluate Fabric Performance Early

You save money when you invest in high-quality fabric. There is no use buying cheap fabric initially and spending huge amounts in replacing the fabric later. (cheap products often are not of good quality). They can lead to:

- Quicker fabric wear

- Decrease is business operations

- Greater replacement costs

Check the product quality before going ahead for bulk buying. You do not want additional charges on replacing the product.

Optimize Order Sizes

You need to know the exact number of products you need. This helps avoid the following:

- Over-ordering product blocks money and needs extra storage space

- Under-ordering will absolutely not serve the purpose as it will not fulfill the actual product requirement.

Use Fabric Blends Wisely

It is always a good idea to mix two fabrics to produce something extraordinary. For instance, When you combine PU coating with mid-range polyester base, you get excellent results at the same time reducing the overall costs.

Partner With Reputable Manufactures and Suppliers

You minimise long term business risks when you tie up with trusted bag fabric manufacturers in India as they provide:

- Top-notch quality in every order

- Transparency throughout the buying process.

- Industry experience in selecting the right fabric appropriate for your business.

Table: Cost-Reduction Strategies for Bulk Fabric Buyers

|

Strategy

|

How It Reduces Cost

|

Notes

|

|

Understand Requirements

|

Avoids overbuying or ordering unsuitable fabric

|

Save on reorders and waste

|

|

Manufacturer vs Distributor

|

Lower per-unit cost when buying direct

|

Evaluate minimum order quantity

|

|

Negotiate Terms

|

Bulk discounts, flexible payments

|

Build long-term relationships

|

|

Evaluate Fabric Performance

|

Reduces returns & replacement costs

|

Perform small-scale tests

|

|

Optimize Order Sizes

|

Balances inventory & cash flow

|

Use consumption projections

|

|

Use Material Blends

|

Lowers material expenses

|

Maintain performance in critical areas

|

|

Partner With Reputable Manufacturer

|

Minimizes risk & hidden costs

|

Optional, recommended for large orders

|

Conclusion

Following the above mentioned strategies, you can ensure that you get high-quality fabrics at great prices. Bulk buying does not have to compromise with product quality. Kalra Canvas- a trusted bag fabric manufacturer in India takes care of all your fabric bulk orders.

Contact us today for more details.