As a manufacturer or a supplier in the bag manufacturing industry, it is vital to select the right one depending on what you need. As there are so many types of bag fabric in the market, it is only important to know a bit about each type so that you can make a better decision.

Each type of bag fabric serves a different purpose. From schoolbag fabric to digitally printed bag fabric, each one is designed for a specific purpose. Listed below are the 10 most common types of bag fabrics.

10 Types of Bag Fabrics You Should Know About

1. Heavy-Duty Bag Fabrics

Overview

Heavy Duty Bag Fabrics are built to survive rough use or heavyweight loads. Such materials work great for packs facing constant stress, whether outdoors or bulky stuff.

Common Materials:

- 600D Polyester

- Ballistic Nylon

- Canvas

- Oxford Fabric

Applications:

- Travel bags

- Tool bags

- Camping or tactical rucksacks

B2B Insight:

Producers ought to get tough sack materials from vendors providing scratch resistance, sun shielding, or water-resistant layers – traits crucial for lasting strength alongside happy buyers.

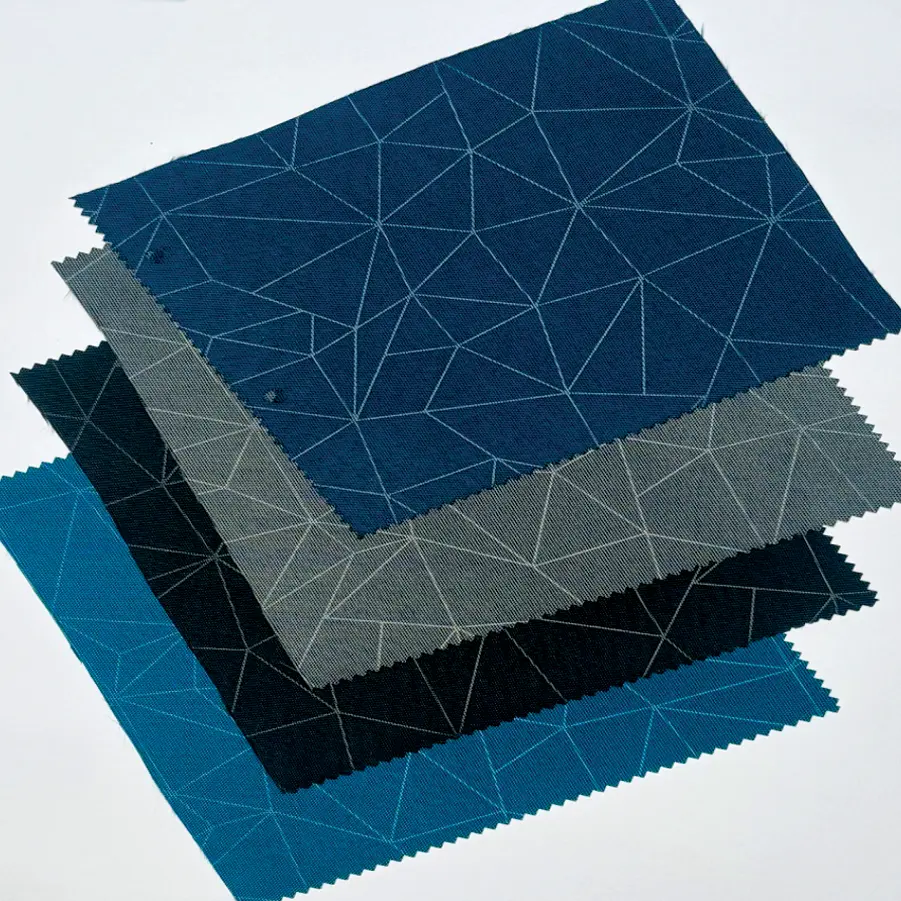

2. Printed Bag Fabrics

Overview

Wrapped materials with designs boost product look and brand vibe. These show up a lot in promo totes, grocery carriers, or everyday gear.

Techniques Used:

- Screen printing

- Sublimation printing

- Heat transfer

- Digital printing

Applications:

- Custom-printed totes

- Branded merchandise bags

- Retail packaging

B2B Insight:

Companies making tailored fabric bags let producers sell more kinds of items without stocking much. When orders go big, each piece ends up cheaper.

3. Polyester Bag Fabric

Overview

Polyester shows up everywhere in bags because it’s tough and cheap while handling rain well.

Features:

- Lightweight yet strong

- Fights shrinking while staying firm against pulling

- Fast drying yet simple to wipe down

Applications:

- Backpacks

- Duffel bags

- Laptop sleeves

- School plus journey sacks

B2B Insight:

While choosing Polyester Bag Fabric, always check details such as denier count – like 300D, 600D, or 900D – alongside PU or PVC layers that boost resistance to moisture. Contacting a reliable Bag Fabric manufacturer in India ensures consistent fabric quality.

4. Digital Printed Bag Fabric

Overview

Digital printing changed how bags are made – now sharp, colourful patterns go straight onto cloth without fuss.

Benefits:

- No color limitations

- Small order sizes accepted

- Perfect when you need just a few – or something unique

Applications:

- Fashion handbags

- Promotional bags

- Limited-edition designer bags

B2B Insight:

For makers who sell to businesses, Digital Printed Bags Fabric work well - giving unique designs that grab the attention of today’s detail-focused shoppers.

5. Luggage Bag Fabric

Overview

- Luggage materials must handle heavy wear, resist knocks, and also shrug off water.

- Common Materials:

- 1680D Ballistic Nylon

- Polyester Oxford

- Polycarbonate-coated blends

Applications:

- Suitcases

- Trolleys

- Travel duffels

B2B Insight:

Pick suitcase materials checked for rip toughness, how well the coating sticks, and also their ability to handle surface wear, so they fit international sale rules. Bulk buyers usually source from leading Luggage Bag Fabric manufacturers in India, like Kalra Canvas, for high-quality, export-ready materials.

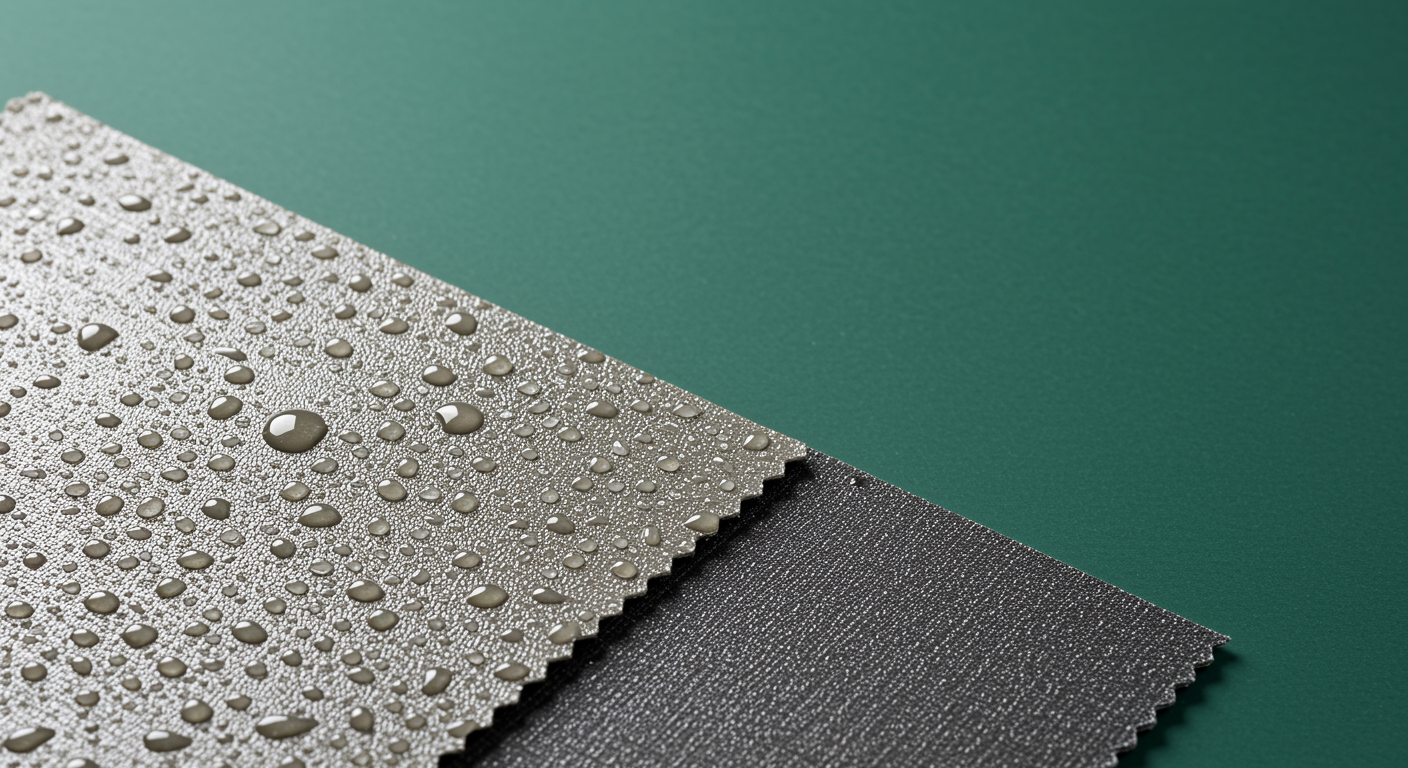

6. Backpack Bag Fabric

Overview

Backpack materials need to handle toughness, feel good on the shoulders, and yet look decent.

Features:

- Water-repellent finish

- Tear-resistant

- Air-friendly fabric choices inside

Applications:

- Hiking, but also travel packs.

- Laptop or commuter sacks

B2B Insight:

Premier makers of bag materials offer coated fabrics using polyurethane, along with layered builds – tailored for varying load needs and damp conditions.

7. Polyester Lining Fabric

Overview

Polyester liner? That’s the quiet powerhouse behind bags – giving shape, shielding stitches inside, and also boosting how long they last.

Features:

- Smooth, lightweight texture

- Offered in basic or patterned styles

- High color fastness

Applications:

Fabric on the inside of purses is also used in rucksacks or small cases for carrying money.

B2B Insight:

When getting Polyester Lining Fabric in large amounts, buyers ought to focus on steady weight per square metre – also make sure the colouring is uniform while including static-resistant treatment. Collaborating with manufacturers like Kalra Canvas helps you get the best-in-class products.

8. Bag Lining Fabric

Overview

Some bag linings use polyester; others go for nylon or mixes with cotton. These insides make the look cleaner while adding strength inside.

Applications:

Inside pockets of backpacks, suitcases, or sports bags

B2B Insight:

In business manufacturing, picking liner materials usually matches how a brand wants to be seen – high-end tote bags go with satin or twill, whereas work-focused styles stick to tough polyester taffeta.

9. School Bag Fabric

Overview

A backpack’s material should last long and shrug off rain, and also come in bright shades so kids like them even after months of wear and tear.

Common Choices:

- 600D or maybe 900D polyester

- PU-coated Nylon

- Printed Oxford Fabric

Applications:

- Backpacks

- Trolley school bags

- Lunch plus tote packs

B2B Insight:

Bulk producers of backpacks usually go for tough polyester or nylon fabrics that keep their color even after lots of wear from kids and young people. These materials don’t sag easily, standing up well to daily rough handling without losing form.

10. PVC and PU (Synthetic Leather / Faux Leather)

Overview

- PVC, which stands for Polyvinyl Chloride, along with PU – short for Polyurethane – are man-made materials designed to mimic genuine leather’s rich appearance and soft texture.

Features:

- Resists water yet wipes down fast

- Choose from flat, shiny, or rough surface options

- Cheap substitute for real hide

Applications:

- Executive laptop bags

- Handbags

- Business presents plus high-end travel bags

B2B Insight:

- Manufacturers like PU Coated Fabric because it’s softer and more flexible, whereas PVC works better when you need something stiff for shaped bags. People often pick these fabrics when making high-end luggage meant to be shipped overseas.

- Available in matte, glossy, or textured finishes

Here is a comparison table for all 10 types of bag fabrics.

|

Bag Fabric Type

|

Durability

|

Cost

|

Applications

|

As

|

|

Heavy-Duty Bag Fabrics

|

Very High

|

Medium–High

|

Travel bags, backpacks, tool bags

|

Ideal for rugged use; needs suppliers with abrasion-resistant options

|

|

Printed Bag Fabrics

|

Medium

|

Low–Medium

|

Tote bags, promotional bags

|

Great for customization; low MOQ options available for bulk buyers

|

|

Polyester Bag Fabric

|

High

|

Low–Medium

|

Backpacks, school bags, laptop sleeves

|

Widely available, versatile, and cost-effective for

|

|

Digital Printed Bag Fabric

|

Medium

|

Medium

|

Fashion bags, promotional bags

|

Perfect for short-run or limited-edition collections; high design flexibility

|

|

Luggage Bag Fabric

|

Very High

|

Medium–High

|

Suitcases, travel duffels

|

Must meet tear-strength & coating requirements; crucial for export-quality products

|

|

Backpack Bag Fabric

|

High

|

Medium

|

Hiking, school, laptop backpacks

|

Balances comfort, durability & water resistance; PU-coated or laminated options preferred

|

|

Polyester Lining Fabric

|

Medium

|

Low

|

Bag interiors

|

Adds structure & durability; consistent GSM & colorfastness is important for bulk buyers

|

|

Bag Lining Fabric

|

Medium

|

Low–Medium

|

Inner compartments for all bag types

|

Premium bags may require satin or twill; budget bags use polyester or nylon

|

|

School Bag Fabric

|

High

|

Low–Medium

|

Backpacks, trolley bags

|

Colorfast, durable, and water-resistant; ideal for bulk school bag production

|

|

PVC & PU (Synthetic Leather / Faux Leather)

|

Medium–High

|

Medium–High

|

Executive bags, handbags, luggage

|

PU = soft & flexible; PVC = rigid & structured; popular for premium bag lines

|

Conclusion

Picking a good material for bags helps mix looks, price, and how long it lasts. For makers, sellers, or those shipping them out, knowing the differences between strong textiles, poly-based fibres, printed patterns, synthetic leather alternatives, and inner coverings means tighter checks on standards and smarter market placement.

In business deals, how steady the material is, how well it’s tested, plus whether you can count on the source – all shape how people see your brand. Work only with dependable suppliers of bag cloth and bulk sellers that provide solid stuff when needed, without going over-cost. Working with specialised vendors like a Luggage Bag Fabric Manufacturer in India or cotton-based suppliers for cotton canvas tote bag production can elevate your product lines for domestic and international markets.

FAQs

1. Which material holds up best in tough bags?

Sturdy polyester, like 600D to 1680D, works well for tough carryalls; meanwhile, ballistic nylon holds up just as strong when used outdoors.

2. What material works well for backpacks that kids use at school?

600D polyester, along with PU-treated nylon, stands up well to wear, keeps colours bright, and resists moisture – perfect when making backpacks for students.

3. How come PU isn't the same as PVC when it comes to fabric?

PU feels smoother, bends more easily, and works well for high-end tote styles – meanwhile, PVC holds its shape better and is commonly found in rigid suitcases.

Because it's tough, dries fast, works well outdoors, and holds shape over time.

Polytope is light, cheap, and tough – so it works well for clothes or tote ranges when you need crisp prints.

4. Which kind of inner cloth works best for makers?

Polyester or nylon taffeta inside layers work better because they last longer, feel slick, and also clean up fast, no matter the bag style.